Borescopes for Medical Device Manufacturing

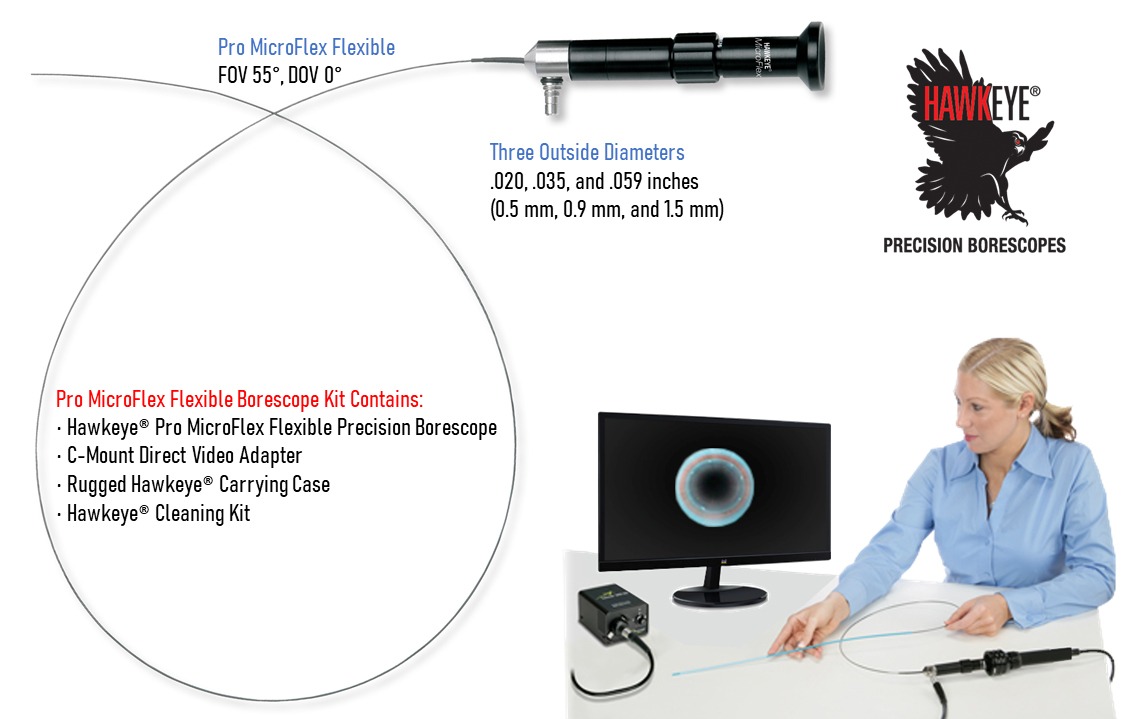

In medical device manufacturing, borescopes play a critical role in ensuring precision, quality, and compliance with strict regulatory standards. These advanced inspection tools enable engineers and quality control specialists to visually examine intricate internal components of medical devices without disassembly. By inserting a borescope into small openings or channels, inspectors can meticulously inspect for defects such as machining irregularities, assembly errors, or contamination, which could impact device performance or patient safety.

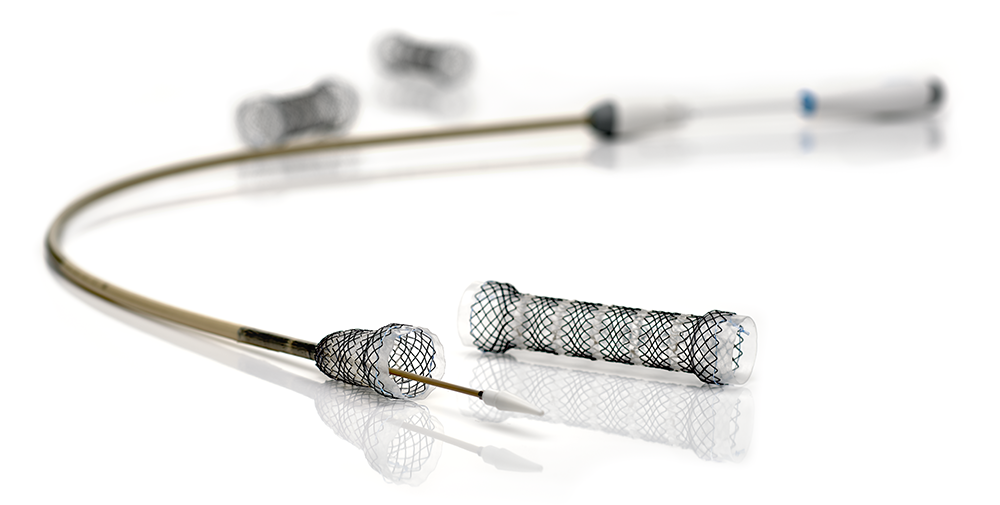

Borescopes are essential during both the assembly and post-assembly phases of medical device production. They facilitate detailed inspections of crucial components like catheters, endoscopes, and surgical instruments, ensuring they meet exact specifications and are free from imperfections that might affect functionality or sterility. Additionally, borescopes help verify the integrity of seals, welds, and bonding processes, vital for maintaining sterile conditions in medical settings. By providing clear, high-resolution images and videos of internal surfaces, borescopes enable manufacturers to identify and address potential issues early in production, enhancing product reliability and reducing the risk of recalls or compliance issues.