How To Inspect a Combustion Chamber

July 7, 2021

Each working part of aviation machinery is integral to a flight’s safety and overall success. So the regular inspection and maintenance of these parts are crucial to ensuring that your equipment’s quality and functionality stay intact. Of these parts, the combustion chamber is one of the most important, as its primary responsibility is to provide enough force to keep a plane in motion. More than that, combustion chambers are a critical element in guaranteeing that the massive engines that jets and planes utilize function correctly. But with the many intricate features to consider, you may find it challenging to understand the best ways to investigate it for issues. Fortunately, this quick guide on how to inspect a combustion chamber goes over the basics of the process so that you can gather the best tools and resources for a quality inspection.

Understand the Function of Combustion Chambers

Before you start the process of inspecting a combustion chamber, it’s crucial to know what it is and how it contributes to the proper functionality of your machinery. The combustion chamber is an area within the engine where a mixture of fuel and air is tightly compressed, causing an ignition. As pistons compress the mixture, it contacts a spark plug and combusts, forcing it out of the chamber in the form of energy.

This combustion process helps the engine “breathe” well, contributing to airflow throughout the engine and ensuring that the motor provides enough force and forward thrust for a jet or plane to fly safely and efficiently. Because they are essentially responsible for a plane’s ability to fly, combustion chambers are a critical part that you should inspect for damage and maintain regularly. Once you can grasp what this piece does, you’ll be ready to start your assessment of it.

Investigate Basic Issues First and Follow Inspection Guidelines

There are specific issues that present themselves more obviously than others in a combustion chamber, and it is always wise to check for these first. Additionally, you’ll need to follow some specific protocols and guidelines closely to guarantee that you can quickly address and repair any observed damages or issues.

First, the external combustion case is a vital part that you’ll need to examine for evidence of hotspots, exhaust leaks, and any distortions before you open the case. Common things to look for are cracks, dents, and nicks. You’ll also want to note any pits or signs of corrosion around the fuel drain bosses, as these often indicate damage and a need for repair. You can assess these types of issues using a visible dye or the fluorescent penetrant inspection method. Both procedures will ensure that any indistinct damages you might have missed will become visible.

Once the combustion covers are open, inspect the chamber for localized overheating, cracks, or excessive wear. Additionally, investigate the first stage turbine blades and nozzle guide vanes for damages, as well as warping and foreign object debris (FOD). Finally, it’s equally imperative to check the combustion chamber outlet ducts and turbine nozzle for cracks and foreign object debris.

Perform an Additional Examination of the Chamber With a Borescope

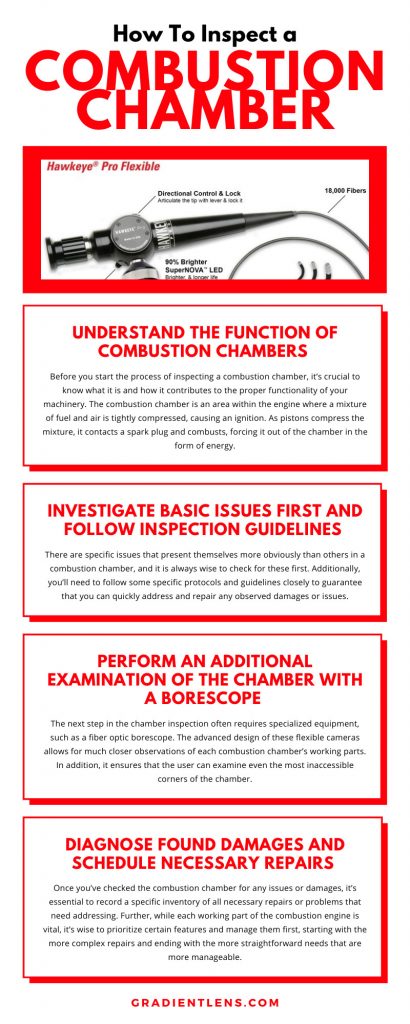

The next step in the chamber inspection often requires specialized equipment, such as a fiber optic borescope. The advanced design of these flexible cameras allows for much closer observations of each combustion chamber’s working parts. In addition, it ensures that the user can examine even the most inaccessible corners of the chamber.

This equipment is invaluable to a successful inspection and quality combustion chamber maintenance, especially when certain elements exist in the part’s anatomy. For instance, the combustion chamber might have complex access components, such as cross holes, undercuts, or deep bores. Additionally, a borescope inspection will also be necessary if any of the combustion chamber’s critical elements are hard to see or access without that equipment.

Borescopes can also detect issues such as cracking and corrosion; however, they’re particular in their enhanced ability to find other kinds of damage like hot spots that indicate uneven flame distribution and additional corrosion on housing welds. Borescopes are also unique in their ability to catch more minor problems that are not as readily observable by the naked eye, ensuring that every inspection is thorough and of the highest quality.

Diagnose Found Damages and Schedule Necessary Repairs

Once you’ve checked the combustion chamber for any issues or damages, it’s essential to record a specific inventory of all necessary repairs or problems that need addressing. Further, while each working part of the combustion engine is vital, it’s wise to prioritize certain features and manage them first, starting with the more complex repairs and ending with the more straightforward needs that are more manageable.

For instance, two cracks on the chamber that have progressed to the point of nearly meeting could allow turbine damage to break loose, usually indicating that the entire combustion chamber will need replacing. Significant damages of this nature need immediate repair, first and foremost. Inversely, considerably less significant damages, such as cracks on the chamber’s front liner emanating from air holes, are considered acceptable, given that they do not exceed the appropriate limits.

Also, when inspecting the combustion chamber, disassembly of the engine is often necessary. For this reason, it’s of critical importance to keep track of each part you remove and follow directions closely for their reassembly once the inspection is complete. This part of the process is of the utmost importance, as proper reassembly will help prevent serious complications down the line and ensure that the part will continue to function at its highest capacity.

Each part of your aviation equipment is integral to the success of its overall functionality, so it’s crucial to understand the job of each piece and take the proper steps to perform high-quality inspections and maintenance on them regularly. Combustion chambers are easily one of the most vital of these parts, and because of their intricate nature, the inspection process might seem overwhelming. However, being aware of the basics of how to inspect a combustion chamber can help you feel more confident throughout the process.