Gearbox Inspection

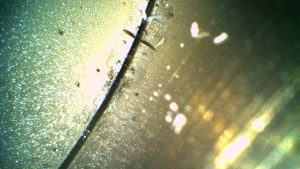

Borescopes are essential for gearbox inspection in power generation, allowing engineers to conduct thorough examinations of internal components without full disassembly. These advanced inspection tools are inserted through small openings or inspection ports to visually assess gears, bearings, and shafts within gearboxes. By capturing high-resolution images and videos, borescopes enable inspectors to detect wear, pitting, cracks, or other damage that could impact gearbox performance.

During gearbox maintenance and troubleshooting, borescopes play a critical role in identifying early signs of potential failures. Engineers use them to inspect crucial components deep within the gearbox, such as gear teeth and bearing surfaces, to evaluate their condition and lubrication levels. This proactive approach helps prevent costly downtime and repairs by addressing issues before they escalate. Additionally, borescopes verify the effectiveness of gearbox repairs and ensure correct reassembly and alignment of components, promoting optimal gearbox function and durability in power generation applications.

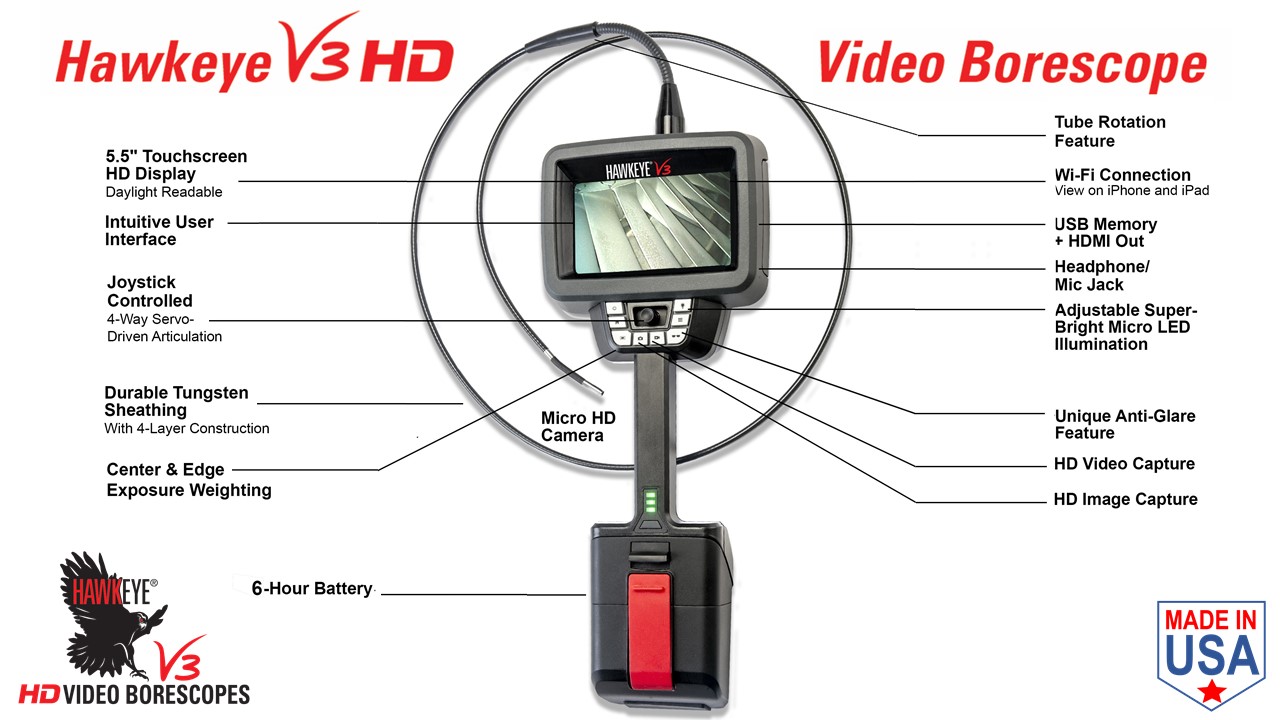

Gearbox inspection using a V3 4mm HD Video Borescope.

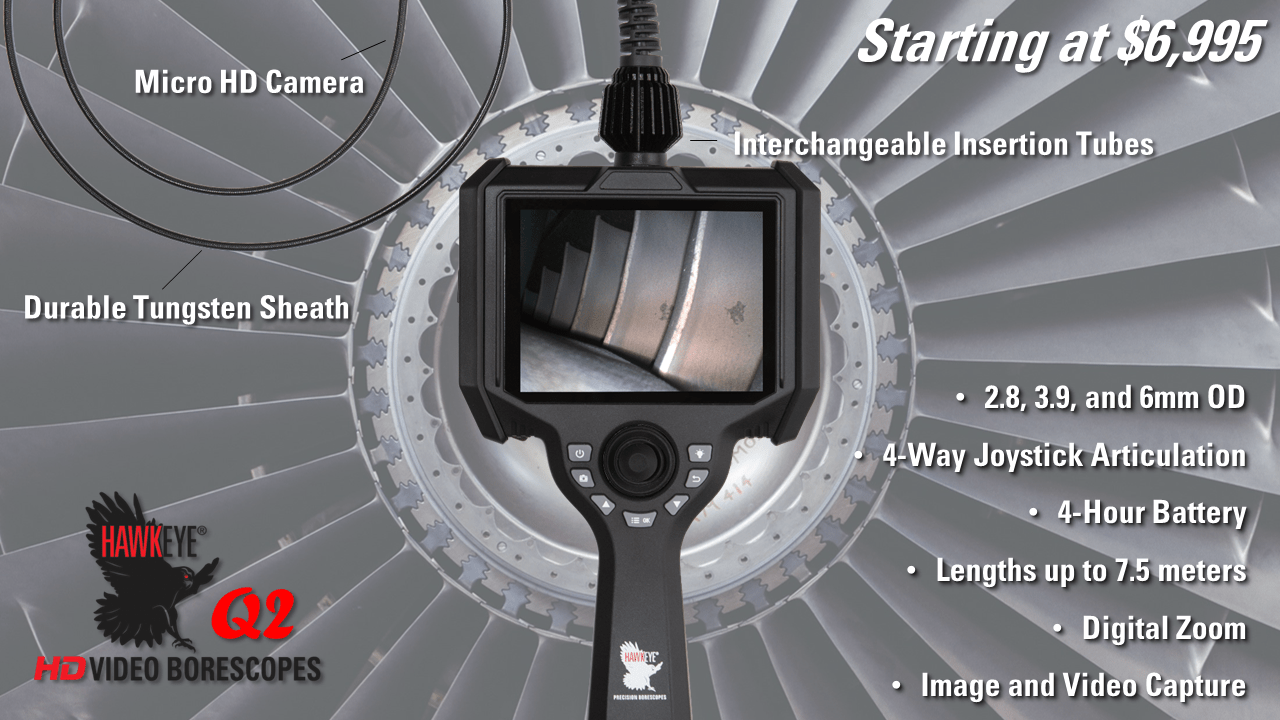

Gearbox inspection with a Q2 3.9mm HD Video Borescope.

Gearbox inspection with a V3 HD Video Borescope.